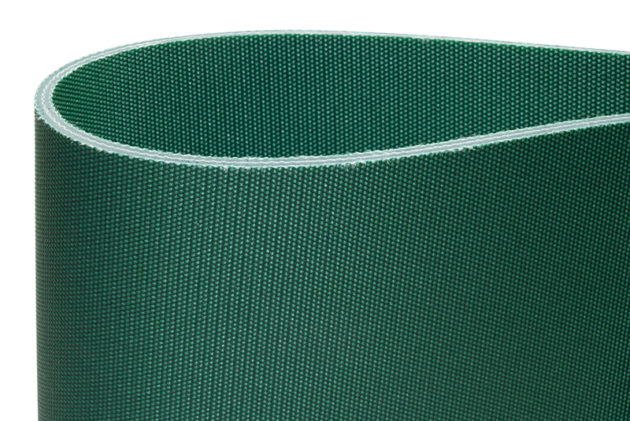

PVCCON are standards belts for general conveying purposes.

Big variety of characteristics combinations and top cover structures to meet all possible conveying requirements (in floor, decline, incline).

They are made with different cover hardness, surface patterns, colors.

PVCCON

Standard conveyor

PVCCON

PVC, LIMITED OIL RESISTANT

SKU

PVCCON-1

Features

Resistant to oil abrasion, water.

Medium and high grip.

Working temperature

-10°C / +70°C

90° Shore A top cover. Matt surface PVC. High resistance to abrasion of the carrying surface. Conveyors for product accumulation and transverse detectors, magnetic elevators for cans, wood shaving equipment, cutting machines and automatic die cutting machines.

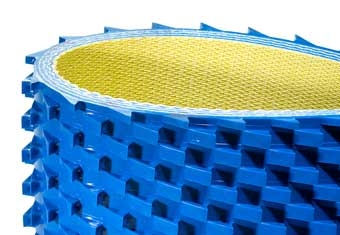

Soft, 46 to 55 Shore A PVC cover hardness belts. Belts in this range have a very elastic and soft cover with a very high coefficient of friction. The large variety of patterns ensures the availability of the right belt for any application where a high grip is required. “H” saw-tooth structure is used on steep conveyors. Type L91/V is specific for marble and ceramic polishing machines whenever a high coefficient of friction is required.

| Sampla REF | Article NO | Description | Product PDF |

|---|---|---|---|

| L20/BW | KA2PG2301 | PVCCON | 2R-RX/14 PG23 00/BW AS | Download |

| L91/H | KA3PG1H01 | PVCCON | 3F/50 PG120 U0/H | Download |

| L30/BW | KA1PG3001 | PVCCON | 1FH/20 PG30 V0/BW AS | Download |

| L10/F | KA2GR2401 | PVCCON | 2LR/8 GR24 00/F | Download |

| L10/LG | KA2GR2601 | PVCCON | 2LR/8 GR26 00/LG | Download |

| L10/Y | KA2GR2801 | PVCCON | 2LR/8 GR28 00/Y | Download |

| L10/V | KA2PG2401 | PVCCON | 2LR/8 PG24 00/V | Download |

| L20/LG/NR | KA2BL3008 | PVCCON | 2R-RX/14 B30 00/LG AS | Download |

| L20/LG/VR | KA2PG3004 | PVCCON | 2R-RX/14 PG30 00/LG AS | Download |

| L10/M | KA2PG5201 | PVCCON | 2LR/8 PG52 00/M | Download |

| L10/M/NR | KA2BL5201 | PVCCON | 2LR/8 B52 00/M | Download |

| L20/M | KA2PG5701 | PVCCON | 2R/12 PG57 00/M | Download |

| L20/C | KA2PG5601 | PVCCON | 2R/12 PG56 00/C | Download |

| L20/H | KA2PG8501 | PVCCON | 2R/12 PG85 00/H | Download |

| L30/AS | KA3PG6001 | PVCCON | 3R/16 PG60 00/V30 AS | Download |

| L91/V | KA3PG7002 | PVCCON | 3F/50 PG70 V0/V | Download |

55 Shore A cover hardness PVC belts specifically designed for marble, granite and ceramic polishing and gauging machines. Bottom side fabric has a PU impregnation for a low coefficient of friction. These belts usually feature a 4 ply carcass with very low elongation and high resistance to cutting and abrasion. “Y” and “H2” surface patterns allow for easy draining of water and no movement of the marble slab or ceramic product conveyed during polishing. Besides, H3 pattern with “cross teeth” surface structure has been newly added to the standard range with distinguishing features such as perfect gripping surface for polishing machines and avoiding possible arcs during calibration and polishing processes.

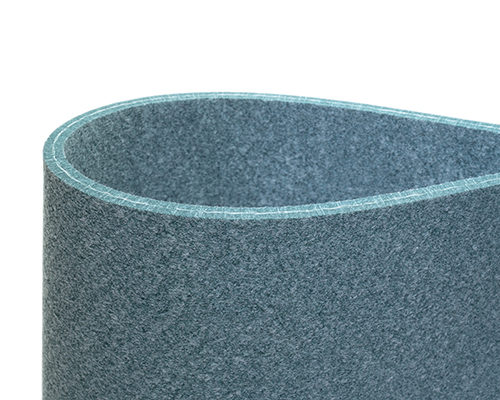

PVC belts with different cover hardness depending on various possible uses. All types are flame retardant as per DIN – ISO AFNOR norms. These belts are used in airport, postal and logistic installations, where low-noise, flame retardant and antistatic properties are requested for safety reasons.

| Sampla REF | Article NO | Description | Product PDF |

|---|---|---|---|

| N18/A | KA2BL2103 | PVCCON | 2R-RX/14 B21 00/V05A AS FR | Download |

| N20/0.0 | KC2BL2401 | FABCON | 2R-RX/14 B24 00/U0 AS FR | Download |

| N20 | KA2BL2602 | PVCCON | 2R-RX/14 B26 00/V05 AS FR | Download |

| N20/A | KA2BL2601 | PVCCON | 2R-RX/14 B26 00/V05A AS FR | Download |

| N20/10.0/A | KA2BL3005 | PVCCON | 2R-RX/14 B30 00/V10A AS FR | Download |

| N20/BW | KA2BL2302 | PVCCON | 2R-RX/14 B23 00/BW AS FR | Download |

| N20/LG | KA2BL3001 | PVCCON | 2R-RX/14 B30 00/LG AS FR | Download |

| N20/M | KA2BL5701 | PVCCON | 2R-RX/14 B57 00/M AS FR | Download |

74 Shore A hardness PVC belts with good resistance to abrasion and cutting. Suitable for conveying in the presence of mineral oils, hydrocarbons, and detergents. Standard belts for general conveying purposes. Big variety of characteristics combinations and top cover structures to meet all possible conveying requirements. Types U61/V, U91/V and U121/4F are used for stone and ceramics processing machines and have specially designed top cover structures for those applications.

| Sampla REF | Article NO | Description | Product PDF |

|---|---|---|---|

| U20/12.0 | KA2PG3003 | PVCCON | 2R/12 PG30 00/V12 AS | Download |

| U6/05.05/Z/AG | KA1AG2001 | PVCCON | 1R/6 AG20 Z/V05 AS | Download |

| U21/05.05/Z | KA2PG3001 | PVCCON | 2F/13 PG30 Z/V05 AS | Download |

| U10/AG | KA2AG2003 | PVCCON | 2LR/8 AG20 00/V05 AS | Download |

| U20/06.06/Z | KA2PG3002 | PVCCON | 2R/12 PG30 Z/V06 AS | Download |

| U14/AG | KA2AG2002 | PVCCON | 2R/12 AG20 00/V05 AS | Download |

| U20/06.06/NR/Z | KA2BL3003 | PVCCON | 2R/12 B30 Z/V06 AS | Download |

| U14/08.0/AG | KA2AG2401 | PVCCON | 2R/12 AG24 00/V08 AS | Download |

| U20/20.0 | KA2PG3701 | PVCCON | 2R/12 PG37 00/V20 AS | Download |

| U14/11.0/AG | KA2AG2703 | PVCCON | 2R/12 AG27 00/V11 AS | Download |

| U30 | KA3PG3801 | PVCCON | 3R/16 PG38 00/V09 AS | Download |

| U14/15.0/AG | KA2AG3004 | PVCCON | 2R/12 AG30 00/V15 AS | Download |

| U14/06.06/AG/Z | KA2AG3001 | PVCCON | 2R/12 AG30 Z/V06 AS | Download |

| U31 | KA3PG3803 | PVCCON | 3F/14 PG38 00/V08 AS | Download |

| U35/06.06/Z/AG | KA3AG4201 | PVCCON | 3R/16 AG42 Z/V06 AS | Download |

| U35 | KA3PG4501 | PVCCON | 3R/16 PG45 00/V15 AS | Download |

| U6 | KA1PG1301 | PVCCON | 1LR/5 PG13 00/V08 AS | Download |

| U6/05.05/Z/VR | KA1PG2002 | PVCCON | 1R/6 PG20 Z/V05 AS | Download |

| U10 | KA2PG2001 | PVCCON | 2LR/8 PG20 00/V05 AS | Download |

| U35/V | KA3PG5002 | PVCCON | 3R/16 PG50 00/V AS | Download |

| U10/N | KA2PG2002 | PVCCON | 2LR/8 PG22 00/N AS | Download |

| U61/V | KA3PG6501 | PVCCON | 3F/40 PG65 V0/V | Download |

| U20 | KA2PG2501 | PVCCON | 2R/12 PG25 00/V09 AS | Download |

| U91/V | KA3PG7001 | PVCCON | 3F/50 PG70 V0/V | Download |

| U20/Y | KA2PG2901 | PVCCON | 2R/12 PG29 00/Y AS | Download |

| U121/4F | KA4PG9001 | PVCCON | 4F/70 PG90 U0/F | Download |

| U21 | KA2PG2601 | PVCCON | 2F/12 PG26 00/V08 AS | Download |

| U101/V | KA2PG1D01 | PVCCON | 2F/28 PG100 V0/V | Download |

| U19 | KA2PG2703 | PVCCON | 2LR/8 PG27 00/V12 AS | Download |

| U32/NR/A | KA3BL5001 | PVCCON | 3LR-F/25 B50 V0/V20A AS AR | Download |

| U35/Y | KA3PG4901 | PVCCON | 3R/16 PG49 00/Y AS | Download |

Conveyor belts designed for treadmill applications, available with four different patterns and one or two piles versions.

| Sampla REF | Article NO | Description | Product PDF |

|---|---|---|---|

| T8/L | KA1BL1602 | PVCCON | 1RX/6 B16 00/L AS | Download |

| T8/Z | KA1BL1601 | PVCCON | 1RX/6 B16 00/Z AS | Download |

| T8/E | KA1BL2001 | PVCCON | 1RX/6 B20 00/E AS | Download |

| T10/Z | KA2BL2503 | PVCCON | 2F-FX/10 B25 00/Z AS | Download |

| T20/E | KA2BL2505 | PVCCON | 2F-FX/12 B25 00/E AS | Download |

| T20/L | KA2BL2504 | PVCCON | 2F-FX/12 B25 00/L AS | Download |

| T20/P | KA2BL3002 | PVCCON | 2F-FX/12 B30 00/P AS | Download |

Related Products